These systems enable reliable and accurate capture of production and shipment data (which includes parcel or cargo weight,dimensions and identity). The automated cubing systems and dimensional weighing equipment by Walz Scale are built to handle virtually every aspect of package dimensioning, and therefore significantly reduce the overhead costs of the users.

Each system is designed to facilitate both turn-key cubing and a simplified scanning procedure which will provide efficiency and cost-savings for customers. Three primary systems among the line-up of dimensional weighing equipment by Walz comprises of the Static Package Scanner, In-motion Package Scanner, and the Large Freight & Pallet Dimensioning System.

Static Package Scanner

The static package scanner system, formally known as the Walz Cube is made with the advanced engineering and the latest static cubing technology. The Walz Cube provides a reliable, accurate, and cost-effective weighing and scanning solution for warehouses, shipping/receiving operations, and point-of-sale desk applications.The scanner utilizes industrial-grade sensors to give extremely accurate measurements of packages, and the system as a whole is immensely robust and can be used in busy shipping stations and harsh conditions.

The Walz Cube is a cutting-edge cubing system that offers a radically innovative and effective method of managing the weighing and dimensional scanning of shipments. It comes in two models-the Walz Cube (which weighs 62 pounds, and is 27 x 27 x 45 inches) and the larger Walz Cube XL (weighing 75 pounds with dimensions of 35 x 35 x 45 inches).

As turn-key unit, the static package dimensional scanning system can be easily integrated with personal computer software and also applications run by package companies like UPS and TNT. Users can also use internet to transfer the weight data which can be saved in popular file formats such as csv.

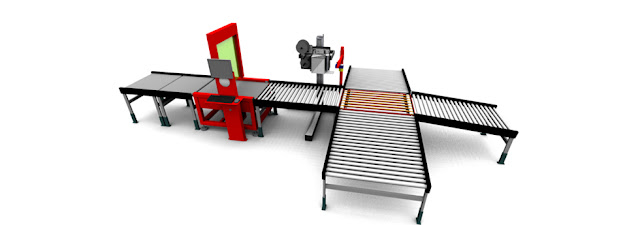

In-motion Package Scanner

This is an advanced, dynamic scanner that gives instantaneous in-motion dimensioning and cubing solutions. It is especially suited for conveyor belt systems due to its high technology that renders it easily integrable with shipping and logistics operations which utilize such systems. The system uses state-of-the-art laser technology to generate exceptionally accurate dimension data while the conveyor belts are still in high speed motion.The in-motion package scanner system is in compliance with the weight standards applied by prominent package firms such as USPS, UPS, FedEx and TNT. It can be incorporated in other conveyor belt systems or used as stand-alone.For organizations focusing on efficient, optimal and cost-effective operations, this system provides turn-key systems that guarantee total automation of all shipping and manifest systems.

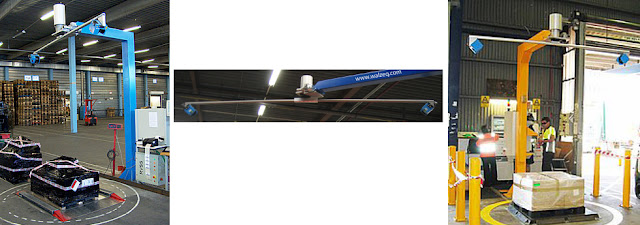

Large Freight & Pallet Dimensioning System

This is an ultra-modern dimensional weighing and scanning systems that utilizes scanners to generate exceedingly accurate dimension data. It is suitable for palletized cargo and large packages that are in a moving conveyor system. The scanner provides dimensional weighing data even while the pallet is in motion.The scanners can be operated in both indoor and outdoor locations. The system includes a data management capability that makes it effectively integrable with a variety of warehouse management applications and systems. The scanners give quick and accurate measurements even when operated under rugged conditions.

These dimensioning and cubing systems developed by Walz can be effective solutions for all shipping and warehousing activities of both organizations and individuals. They are highly advanced systems that are save time and money for users. They feature intuitive interfaces and are flexible enough to integrate with many warehousing and supply chain management systems. They are easily calibrated and have low maintenance costs.They also come with remote access support.